How To Find Lift Supports By Size

Are you looking for lift support struts or replacements for the old lift support hardware? No matter finding lift supports by size or by application

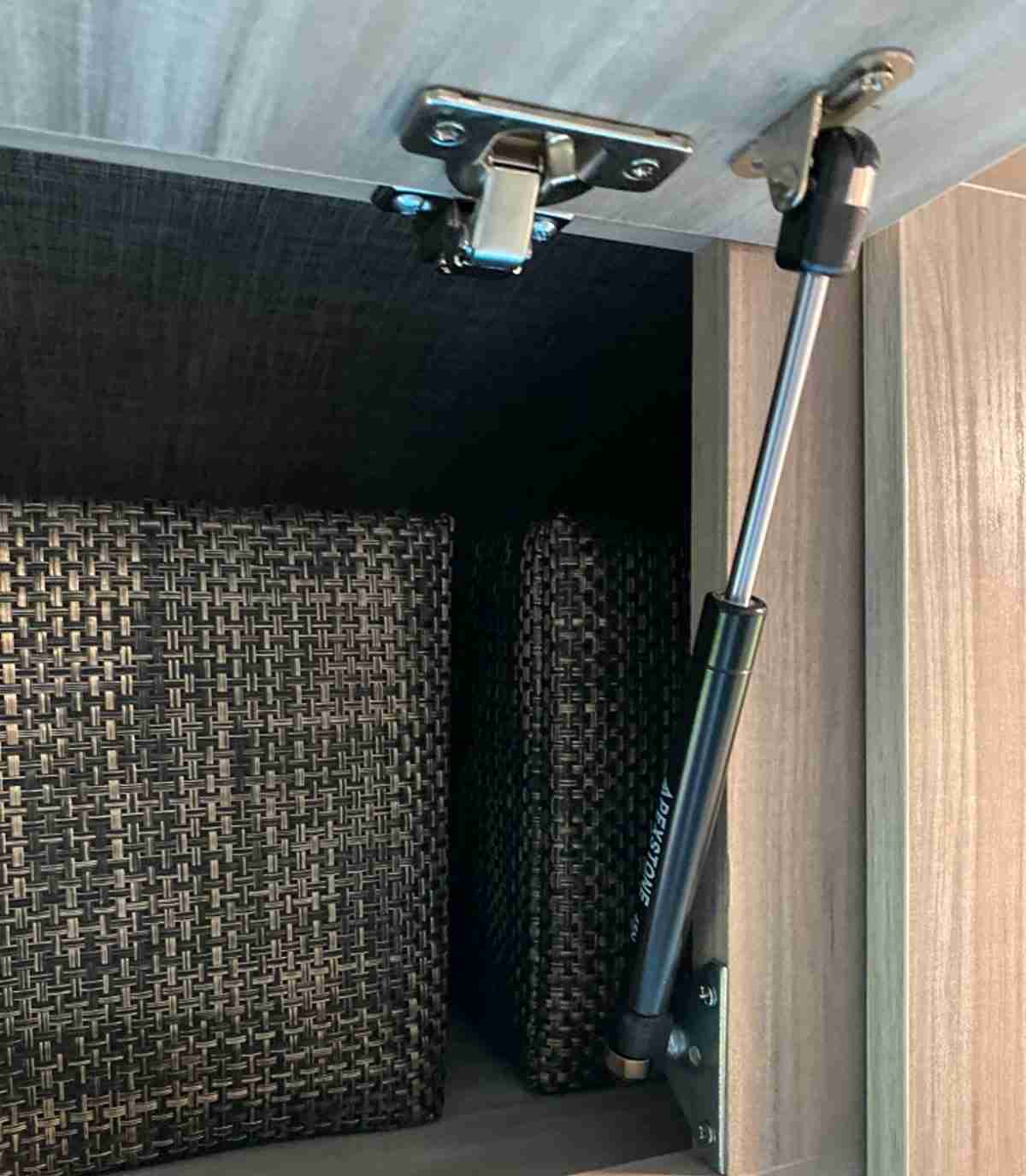

Gas springs, also known as gas struts, use compressed gas to create force and smooth motion. With the ability of motion control and easy of use, they are applied to many applications. By adding pressure to the nitrogen gas and oil sealed within a cylinder, they pushing against the piston, so lift support like trunk struts or rear hatch lift supports help us lift up the trunk or rear hatch effortlessly, and perform well in the application such as office chair, hosiptal beds, examination chairs, and overhead baggage compartments of plane. They make our life more easier.

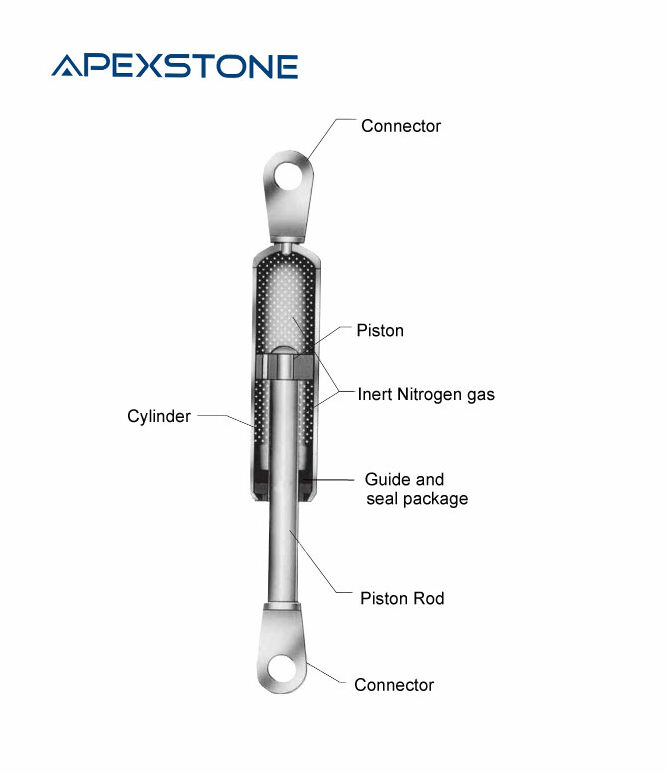

The gas springs mainly include 6 parts, rod, piston, guide and seal package, inert Nitrogen gas, pressure cylinder, and connector. As a quality-focused gas spring manufacturer, we have chosen top-quality components for our gas springs. The sealing guide bushing is crafted from a plastic composite material, while the remaining metal fittings are mainly made of zinc, aluminum, and steel. This ensures greater durability and resistance to corrosion, ultimately leading to a longer lifespan for the support rods.

We can metaphorically compare a gas spring to a customizable ‘airbag’ that can be adjusted for both hardness and elasticity. A mechanical spring is more like an energy storage device. The invention of the mechanical spring owes much to the contributions of the British scientist Robert Hooke. Even though the compression springs were already in use at that time, Hooke introduced “Hooke’s Law,” which states that a spring’s elongation is directly proportional to the force applied to it. This fundamental principle led to the creation of the mechanical spring balance in 1776, utilizing compression springs. Shortly after that, Hooke himself invented springs based on this principle for use in clocks. Springs that adhere to “Hooke’s Law” are the true essence of springs. Over time, as technology advanced, springs found applications in various fields.

The primary differences between industrial gas springs and mechanical springs lie in shock absorption effectiveness, adjustability, lifespan, and application range. They differ in how they operate. In order to gain a deeper understanding of the differences between the two, I have summarized the following five points.

Both industrial gas shock absorbers and mechanical springs can achieve shock absorption, but industrial gas springs provide better shock absorption. This is because the elasticity of compressed air is superior to that of springs, allowing it to absorb and reduce vibrations and impacts more effectively.

Gas shock absorbers offer greater adjustability compared to mechanical springs. They can be adjusted as needed to accommodate different loads and vibration conditions. Mechanical springs have limited adjustability and are challenging to modify once installed.

Gas springs exhibit slightly higher stability than mechanical springs. The elasticity of compressed air provides good stability, meeting specific usage requirements. Mechanical springs also have high stability, but over time, their elasticity may change, necessitating timely replacement.

The service life of mechanical springs is generally longer than that of industrial gas struts but requires regular replacement. Industrial gas struts typically require periodic inspection and maintenance, which, if done correctly, can extend their usable life.

Gas shock absorbers are typically used in precision machinery requiring high accuracy and stability, such as optical instruments, precision testing equipment, aerospace equipment, etc. Mechanical springs have a wide range of applications and can be used in various machinery and equipment.

The gas springs can be roughly categorized into six types: Lockable Gas Springs, Compression Gas Springs, Swivel gas struts, Tension & Traction Gas Springs, Dampers, and Friction Stop Gas Springs.

Lockable Gas Struts are most commonly used in medical devices. These locking gas struts can be stopped at any position during their travel using certain release mechanisms and provide significant locking force (up to 10,000N or more) after stopping.

Compression gas struts are the most widely used. They primarily provide support and have only two positions: fully compressed and fully extended. They cannot stop at intermediate positions during their travel. They find extensive applications in industries such as automotive, textile machinery, printing equipment, office equipment, and construction machinery.

Primarily used in swivel chairs to adjust their positions. They are controllable and pleasantly dampened.

Traction Gas Springs are a unique type, unlike other gas struts that start at their longest position when in a free state and move from longest to shortest when subjected to external forces, traction support rods are in their shortest position in a free state and extend from the shortest to longest when pulled. Traction support rods also come in free and self-locking variants.

A damper or shock absorber is commonly used in automobiles and medical devices. They are characterized by resistance that changes with the speed of operation and provide noticeable damping effects on connected mechanisms.

Friction Stop Gas Springs are mainly used in kitchen furniture and medical equipment. They fall between the features of free-support rods and self-locking support rods: they can stop at any position during their travel without the need for external structures but lack additional locking force.

The elastic pressure of nitrogen gas springs is calculated based on their punching force. In general, when calculating the punching force, it is advisable to increase it by approximately 15% to 20% to better align with real-world conditions. Additionally, when inflating nitrogen gas springs, high-pressure gas can lead to throttling losses, causing a decrease in spring elasticity and some degree of nitrogen leakage, which should also be considered when selecting nitrogen gas springs.

Based on the required stroke and the projects structure’s load points, an appropriate number of gas springs should be chosen to prevent any uneven loading during door operation and facilitate adjustments. This ensures that the nitrogen gas springs have a sufficient lifespan for their intended use.

During the usage of industrial gas springs, dust, dirt, and other impurities can accumulate, affecting their normal performance. Regular cleaning is essential. Use a soft brush or clean cloth to gently wipe the surface of the spring and the surrounding area. Avoid using a too hard brush or applying excessive force to prevent damage to the spring surface.

Industrial gas shocks are controlled by air pressure, so regular checks of pressure stability are crucial. Adjust the air pressure value reasonably according to actual usage to maintain the spring’s normal operation. Additionally, regularly inspect the sealing performance of the stainless steel gas shocks. If any air leaks or poor sealing is detected, promptly carry out repairs or replace the new struts to ensure proper operation.

Lift gas struts should avoid overloading and impacts to prevent damage or failure. Operate strictly according to the rated load and usage specifications of the gas strut to avoid overloading. Before making a purchase, make sure whether you need heavy duty gas springs or small gas springs. When there are impacts or vibrations, consider implementing protective measures such as adding cushioning materials or adjusting the spring’s position to mitigate the effects of impact and vibration on the spring.

Regular inspection and maintenance are essential to ensure the normal operation of industrial shock absorbers. Develop an inspection plan based on actual usage and conduct inspections and maintenance according to the plan. During inspections, check for obvious wear, deformation, or damage on the spring surface and inspect the fastening of connections. If any issues are identified, take appropriate repair measures promptly to ensure the proper operation of the industrial springs.

If you are looking for suitable lift supports, you can refer to this article about how to measure gas struts. If you’ve found this article on “How Do Gas Springs Work” helpful, we’d greatly appreciate it if you could share it with your friends to help more people benefit from this information.

Are you looking for lift support struts or replacements for the old lift support hardware? No matter finding lift supports by size or by application

Are you planning to replace the gas struts on your truck toolbox, either by upgrading the toolbox or replacing worn-out struts? Whether you’re getting it